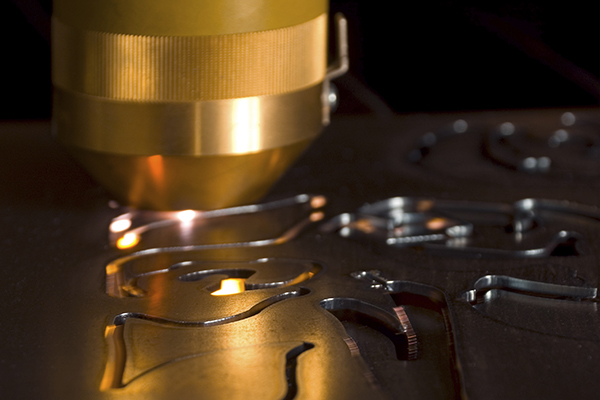

LaserPro™ gases and systems are designed to meet and exceed laser system manufacturer and user requirements including resonator gases, assist gases, process gases. MATHESON also offers related equipment.

As a leading supplier of laser gases, MATHESON has the experience and expertise to make your operation productive and profitable. We provide a complete line of high purity gas products, specifically designed for lasers, including laser resonator gases, laser assist and process gases.

MATHESON provides the total gas supply system, including high quality gas control equipment specifically designed for laser applications. MATHESON can provide customized solutions specific to your requirements, and provide the complete turnkey system.

MATHESON also provides you with one source for all of your laser support service needs. .Contact MATHESON today.

We stand ready to supply gases in bulk, liquid Dewars, tube trailers, or high pressure cylinders. Our qualified laser experts can determine and recommend the best method to meet the specific flow and pressure parameters for your laser.

Gas Equipment for Laser Resonator Gases

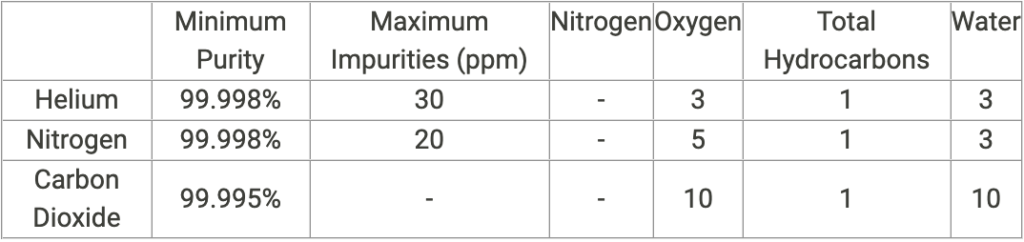

Impurities in resonator gases can damage optics and reduce laser beam quality. Proper high-purity equipment is essential to maintaining the purity of laser gases.

MATHESON’s LaserPro regulators and switchover systems have the same high-quality components (stainless-steel diaphragms, high leak integrity, etc.) used for years in critical laboratory and research applications.

LaserPro switchover systems provide continuous supply of resonator gas eliminating the need to shut down for cylinder changeouts, enhancing productivity. Systems are available for CO2/N2/He premix or for individual pure gases (real time mixing). Rack or wall mount.

Gas Equipment for Laser Assist Gases

Assist gases often require high pressures and flow rates. The MATHESON LPHF Assist Gas Regulators utilize dome-loaded technology to handle this heavy duty application. The advantage of dome-loaded regulators is the stable delivery pressure under varying flow conditions, as well as almost-instantaneous flow when the laser calls for assist gas.

A standard spring-loaded diaphragm regulator experiences some lag time before flows and pressures stabilize. Dome-loaded technology allows for faster piercing times which are especially important if the customer nests many parts on one sheet. The dome-loaded regulators are also very durable, outlasting their spring-loaded counterparts.